Ladder Diagram (LD), Function Block Diagram (FBD), Sequential Function Chart (SFC), and Structured Text (ST) is supported and it includes RSNetWorx for ControlNet, DeviceNet, EtherNet/IP (9357-CNET元, 9357-DNET元, 9357-ENET元 individually or 9357-ANET元 combined), and RsLogix Emulate 5000. If you don't have have a need for Function Block Diagram (FBD), Sequential Function Chart (SFC), or Structured Text (ST), then look at the Standard Edition.ĬompactLogix5370 ControlLogix5500 SoftLogix5800 GuardLogix5500

This one has it all except the additional RsNetWorq softwares. Unless you are configuring Devicenet or Controlnet, then the additional network softwares will not be very helpful to you. This edition is the same as the Standard Edition with the addition of RsNetWorx network configuration software. It also includes RSNetWorx for ControlNet, DeviceNet, EtherNet/IP (9357-CNET元, 9357-DNET元, 9357-ENET元 individually or 9357-ANET元 combined). Function Block Diagram (FBD), Sequential Function Chart (SFC), and Structured Text (ST) is not supported.

#Descargar logix pro full#

If you need Function Block Diagram (FBD), Sequential Function Chart (SFC), or Structured Text (ST) then look at the Full Edition. It connects to all controllers and supports ladder diagram programming which is what most of the PLCs you encounter will be programmed with. This is the edition we recommend for most users and what is installed on most of our PCs. I don't recommend this version unless you specifically have a CompactLogix5370 Compact GuardLogix5300 controller that has Function Block Diagram (FBD), Sequential Function Chart (SFC), or Structured Text (ST) programming in it. Ladder Diagram (LD), Function Block Diagram (FBD), Sequential Function Chart (SFC), and Structured Text (ST) is supported. Overall, I don't recommend it for PLC programmers and integrators since it only works with the CompactLogix5370 Compact GuardLogix5300 which doesn't take a very large machine to outgrow. It may also be good for a maintenance tech supporting a single machine at their plant. This is a really good choice for beginners learning and is what we include with our trainers.

#Descargar logix pro software#

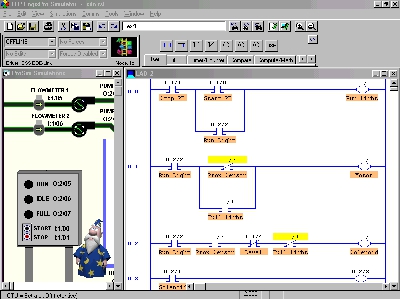

Invest a little more in your software to maintain it. You've invested a substantial amount in your machine. IF PRESSURE DROPS IN LESS THAT 31 SECONDS AT GREATER THAN 48% FLOW, THEN RUN BOTH COMPRESSORS IN THE NEXT CYCLE.CompactLogix5370 ControlLogix5500 SoftLogix5800 Compact GuardLogix5300 GuardLogix5500Īt first glance, this seems to be an excellent choice for maintenance technicians however, the inability to make even minor tweaks to a program could render a machine inoperable until a programmer can arrive. Then timer T4:3 adds and measures this additional control function: If it is longer that 63 seconds, then start the 2nd unit. If you want to add even better control, use Subroutine 3 to control the LED display, and Subroutine 4 for "when 1 is not enough", with 2 additional timers, T4:2 that measures how long it takes a single compressor to fill the tank. See the attached picture for more details. You do this by carefully setting the Setpoint and Span of each pressure switch as follows: You have to use the PE1 pressure switch to start the 1st-run compressor (whether it be Compressor #1 or #2 as determined by the alternator bit B3/0), and then use PE2 to start the 2nd-run compressor if the 1st cannot keep up (pressure continues to drop even if one is running). Please help me out i got this so far i can get the two dual compressors to alternate but i cant get the one dual compressor to go full then drain then both start up.might be made. You should now have a good idea of where improvements BeforeĬontinuing to the next part, run your system with the flow rate adjusted to 78%, 80%, and thenĨ2%, and carefully note the result. Logic, with just a bit more effort you should still be able to even improve upon this. While this current solution likely performs as well as most systems employing relay Your program should now be able to handle both light and heavy demands for air quiteĮffectively.

At 100% loading, both compressors should engage once it isĭetected that the pressure is continuing to drop. When at 50% loading, the compressors shouldĪlternate with each taking a turn. Operation at both 50% and 100% rates of flow.

#Descargar logix pro download#

Once you have created your program, download it to the PLC and thoroughly test out its Please ensure that your system does actually operate in this This action will reduce the time it takes to bring the plant air system up to pressure, and

Is first started and the tank pressure is initially being brought to within range of the pressure It is likely that your modifications will also result in both compressors being run when the system

0 kommentar(er)

0 kommentar(er)